Theodora is a business woman who has made it her life's work to help others achieve success. She has been an entrepreneur since she was young, and has always been drawn to businesses that have the ability to help others. She started her first company when she was just a teenager, and has never looked back since and she like shopping too.

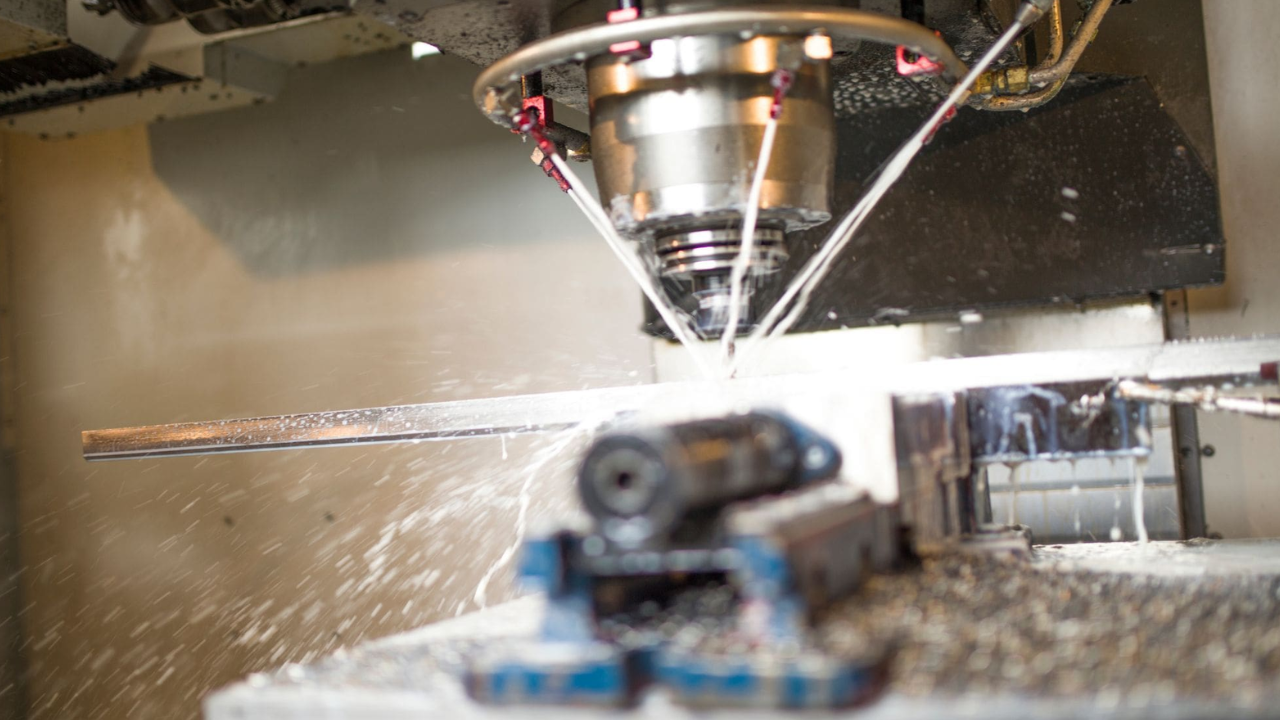

Computer numerical control (CNC) plastic machining is the process of precisely shaping, cutting and finishing plastic parts. This production method guarantees tight tolerances and excellent results because it is very accurate and efficient. Numerous plastic materials, such as acrylics, polyethylene, and polycarbonates, are suitable for CNC plastic machining.

The CNC machines work with plastic workpieces, milling, turning, and drilling them according to preprogrammed instructions. This process is commonly used in sectors where complex and customized plastic parts are necessary, like electronics, automotive, and medical. Because it is affordable, quick to produce, and capable of producing complex geometries, computer numerical controlled cnc plastic machining is the preferred method for creating precise plastic components.

How Are Tools Chosen For Plastic Cutting With A CNC Machine?

The kind of plastic, the required surface smoothness, and tolerances all play a role in the tooling selection process for CNC plastic machining. For general-purpose cutting, carbide end mills are frequently used, however high-speed steel might be more suited for softer plastics. Tool life is increased by coatings like TiN or TiCN. Performance is affected by the helix angle, flute count, and tool shape. When choosing tools, machinists take feed rates, material qualities, and cutting speeds into account to ensure accurate and effective plastic machining.

Plastic Machining With CNC Is A Frequent Use in The Industry.

Because of its accuracy, effectiveness, and adaptability, plastic machining using CNC (Computer Numerical Control) is extensively employed in many different industries. Several sectors frequently employ CNC plastic machining including:

Automotive Industry:

For a considerable amount of time, CNC plastic machining has benefited the automotive industry. CNC plastic machining guarantees the creation of high-precision parts that adhere to stringent industry standards for both external and interior components, such as grilles and bumpers, as well as dashboards, panels, and trim. Plastics are a desirable material for many automobile applications because of their lightweight nature, which also helps with fuel efficiency.

Aerospace Sector:

CNC plastic machining is essential in this sector, where dependability and accuracy are critical. Aircraft interiors, such as seats, cabinets, and control panels, frequently use plastic components. Fuel efficiency and overall aircraft performance are enhanced by the development of lightweight, durable parts that are guaranteed by CNC machining.

Medical Devices and Equipment:

The manufacturing of complex components for medical devices and equipment is largely dependent on CNC plastic machining in the medical sector. CNC machining guarantees the creation of premium, sanitary, and biocompatible plastic parts for everything from precise surgical tools to robust but lightweight diagnostic machine components.

Electronics and Consumer Goods:

The electronics sector gains from the use of CNC plastic machining in the production of electronic device casings, enclosures, and other parts. The method makes it possible to create elaborate designs while preserving the structural integrity needed to safeguard delicate electrical parts. Additionally, plastic components made by CNC machining are frequently found in consumer goods like toys and appliances.

Packaging Industry:

To make unique molds and dies for the manufacture of plastic packaging materials, the packaging industry makes extensive use of CNC plastic machining. Intricate packaging designs may be manufactured precisely and efficiently thanks to technology, which enhances both appearance and usefulness.

Telecommunications:

The manufacture of housings, connections, and other parts necessary for a variety of devices is dependent on CNC plastic machining in the telecom sector. By ensuring that the components adhere to tight tolerances and specifications, the technique makes it easier for them to be seamlessly integrated into intricate communication systems.

Energy Sector:

The fabrication of parts for renewable energy systems, such as solar panels and wind turbines, is done in the energy sector using CNC plastic machining. The effective and dependable functioning of these energy systems depends on plastic components with excellent dimensional precision and durability.

Rapid Manufacturing and Prototyping:

In a variety of industries, CNC plastic machining is the recommended technique for these two processes. Because of its rapid creation of precise prototypes, design concepts may be tested more affordably before full-scale production, resulting in faster cycles for product development.

Bottom Lines

A crucial technology for producing high-quality components for the automotive, aerospace, and medical industries is computer numerically controlled (CNC) plastic machining. It guarantees accuracy and productivity. Because of its adaptability and affordability, it serves as a pillar for innovation, propelling improvements in manufacturing techniques and influencing the development of numerous industries.